Collecting data about assembly lines, trucks, and mining gear and then sending it to humans to help improve the performance of that equipment is pretty well accepted by now. But the Internet of things— the billions of Internet-connected devices used by businesses and consumers—is also permeating the fine art of beer making.

Collecting data about assembly lines, trucks, and mining gear and then sending it to humans to help improve the performance of that equipment is pretty well accepted by now. But the Internet of things— the billions of Internet-connected devices used by businesses and consumers—is also permeating the fine art of beer making.

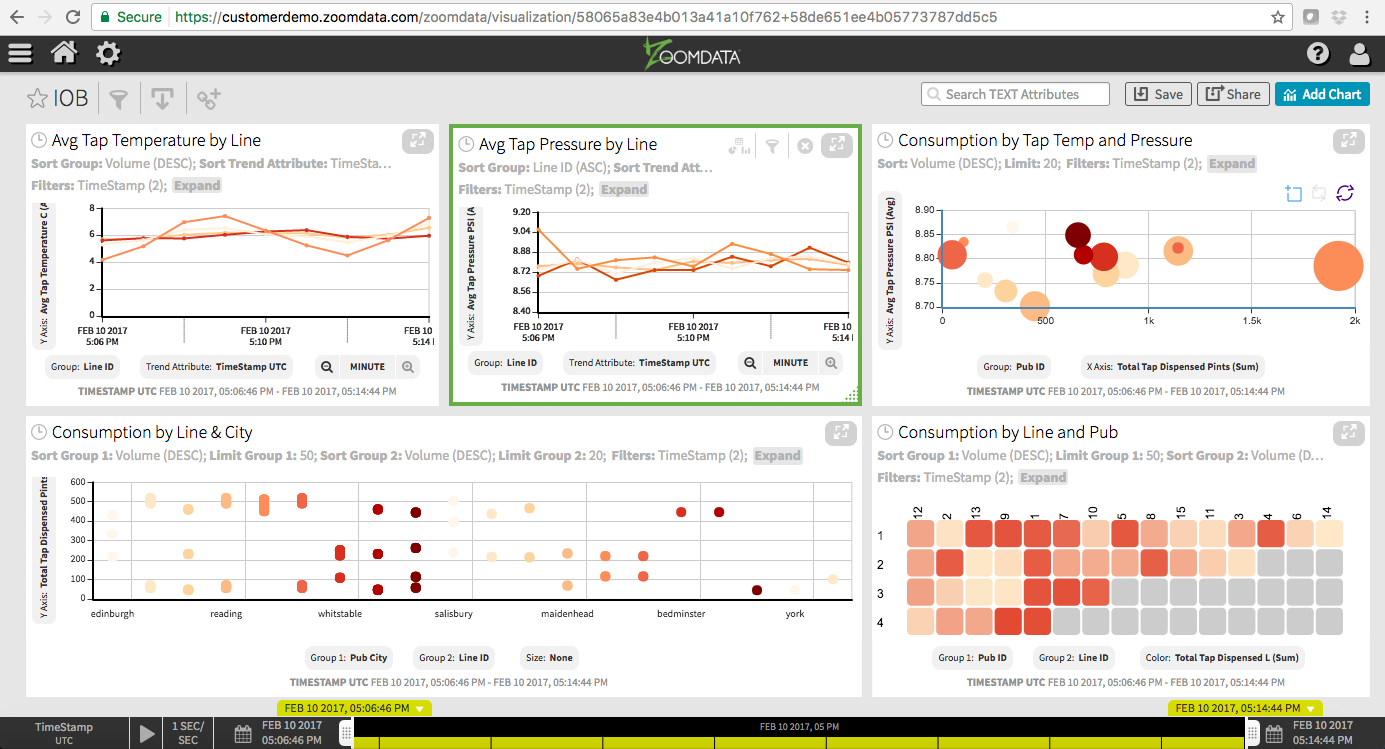

This week, business software makers Informatica and Zoomdata said they are collaborating to help a large, unnamed European beer maker check the quality of its products, from the brewery to the pub. The software will monitor temperature and pressure of the beer in the tap and the line along with tracking the number of pints poured in real time, the companies said.

Get Data Sheet, Fortune’s technology newsletter.

That information could come in handy both for the beer maker and affiliated pub owners, who need to know about inventory and quality levels. Note to bartenders who have been giving friends a lot of free drinks: Your boss may soon be paying closer attention.

Related: Informatica to Be Taken Private

This “Internet of Beers” scenario combines the use of Informatica’s Intelligent Streaming software, which collects and transmits real-time data from various sensors or other devices, with Zoomdata’s visualization tools that put that data in charts that are easier for the human eye to understand than a flood of numbers.

And, with Zoomdata’s product, beer aficionados can play back their data like a DVR. For example, they can pause flow of data, rewind it, and watch it again to see what is happening. Both companies will pitch this system later this week at the Informatica World conference in San Francisco.

Related: Startup Zoomdata Snags $25 million to take on Tableau

To be fair, these companies are not the first to pitch this “Internet of beers” angle. In February, beer maker MillerCoors previewed Miller Lite On-Demand, a service that lets customers order beer from home by telling their Amazon Echo connected device what they need. Or, they can re-stock by pressing a connected Amazon (AMZN, -0.35%) Dash button dedicated to MillerCoors products, according to AdAge.

And SteadyServ, a Fishers, IN. company, has offered a cloud-based beer inventory management system for a few years now that also relies on connected sensors to relay information about what’s happening in unseen parts of the system to the people who need to know about such things as inventory levels.

One perk is that bar staff no longer have to try to lift 165-lb kegs to see how full they are. Instead they can just check level on their smartphones.

[“Source-fortune”]